Siemens PLM NXfor Windows

App info

Everything you need for quality modeling

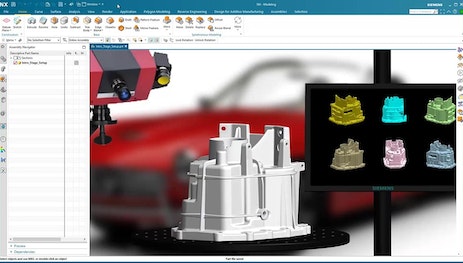

NX is a CAD/CAM/CAE system from Siemens PLM Software. The program uses the Parasolid geometric modeling core. NX supports various operating systems, including Windows.

What is this program?

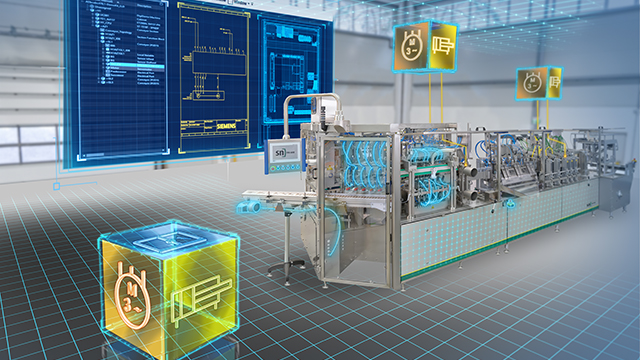

Siemens PLM NX for Windows is a flexible and powerful integrated solution that can help you bring new products to the market faster and more efficiently. NX is the next generation of design, numerical simulation, and manufacturing solutions that allow companies to maximize the potential of digital twins.

NX supports all phases of product development, from concept and design to manufacturing. This toolset allows you to align across disciplines, ensure data integrity, preserve design intent, and optimize workflow.

Where is this program used?

The NX system allows you to realize almost any design idea. Each new version of the system has advanced functionality. It has ensured Siemens PLM Software's success for more than twenty years.

NX includes a suite of integrated solutions, from standard CADs to complex tools for surface engineering, simulation modeling, electromechanical design, and CNC machine programming. In the last four or five versions of NX, the developers have improved the interaction of the program with the user to create a single standard method of working with all the tools.

The major innovations in NX 7.0 include the development of synchronous technology created by Siemens PLM Software, direct simulation technology, and a unique HD3D technology designed to solve complex data retrieval and workflow tasks.

Design features

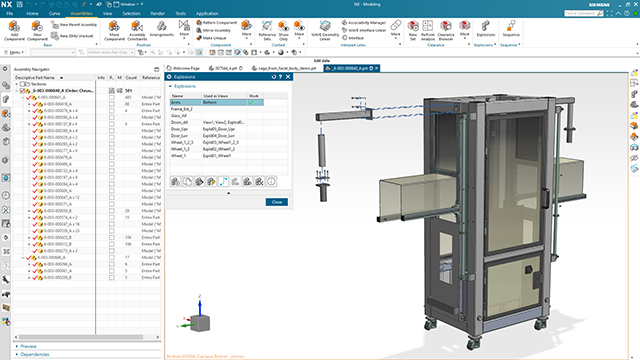

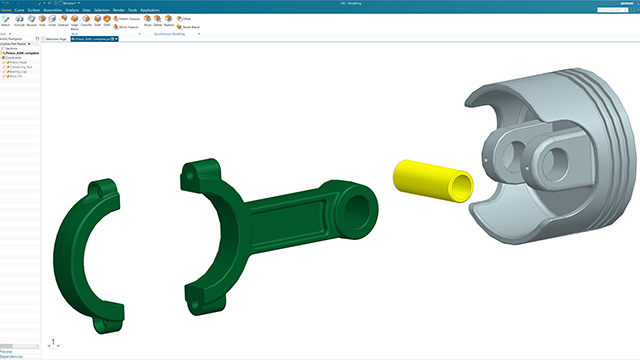

The set of applications included in the NX CAD package allows you to solve the tasks of developing a complete electronic layout of the entire product and its components for subsequent use in the process of technological preparation of production.

The functionality of this application allows you to automate the stages of product design and release design documentation in various forms of representation. Both "bottom-up" and "top-down" design technologies are supported, with the ability to build end-to-end development processes from product requirements to the data output stage of production.

Tools for industrial design

Industrial design tools in NX are designed to develop the product's external appearance (or interior) and analyze its aesthetic and visual characteristics. This functionality automates design processes for digitizing or creating two-dimensional sketches to analyze the manufacturing processes of exterior design elements and design the appropriate equipment.

The following groups of tools represent design automation tools:

Freeform Shape is a toolset for creating parametric surfaces of any degree of complexity and analyzing the quality of geometry.

Realize Shape is a toolset for creating precise geometry using a subdivision algorithm where the user modifies the geometry by dragging control point markers. This method allows you to create any shape without using complex parametric dependencies, get the geometry, and work with it at all the subsequent stages without conversion.

Dynamic & Photorealistic Rendering is a set of mechanisms for obtaining an actual product image in real-time and sequential mode. In real time, the system automatically updates and regenerates the resulting image whenever the geometry changes. When generating a photo, light sources, materials, textures, environmental parameters, shadowing, and other parameters affecting the resulting image's quality characteristics are considered. Rendering can be performed both interactively and in the background. The mechanism of remote rendering on specialized servers can be used if necessary.

In addition to these tool groups, NX CAD has functionality for reverse engineering tasks that may arise in industrial design processes. This functionality makes it possible to quickly process scanned data in STL or point cloud format and obtain accurate geometry that can be used further in development.

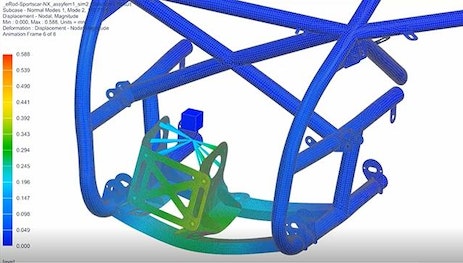

Development of mechanical systems

Siemens PLM NX for Windows allows you to simulate parts and assemblies of a product, perform intersection analysis and mass calculations, and prepare 2D documentation, drawings, or 3D documentation using PMII (dimensions and annotations are applied to the 3D model). The application toolset for modeling parts and assemblies allows users to create a complete digital analog of the unit or component under development, containing the accurate geometry, calculated mass-inertia characteristics, material properties, and all the requirements necessary for manufacturing and inspection.

The capabilities of the system allow modeling products of any degree of complexity and dimensionality, from household appliances to creations of the shipbuilding and aerospace industries. Electronic models created in NX CAD applications are used further in the modules of engineering analysis and technological preparation of production.

Visual reports and HD3D technology

Innovations in synchronous technology develop modeling and geometry editing capabilities. HD3D (High Definition 3D) technology is incredibly effective. It is designed to solve the most complex tasks related to the perception of large amounts of information, geometric and metadata.

Let's consider a typical design organization that has fully embraced 3D modeling and PLM as an example. HD3D provides complete product documentation, its form and functions, and data relevant to the design, production, operation, and utilization.

If you don't know exactly where the information is stored, who created it, or what you are looking for, it isn't easy to get an idea of the current state of a product. 3D model files contain geometry and metadata as documents, such as text, spreadsheets, PDFs, CAD files, etc., associated with each part, assembly, and subassembly. Two systems are used to search for geometry and metadata. Siemens PLM Software products use NX (or 3D model viewers) for geometry and Teamcenter for metadata.

HD3D works with both NX and Teamcenter data, providing access to 3D graphical data and its associated metadata. The data can be viewed and visualized in detail, selecting only the desired information.

For example, you can view the working surface by selecting and visualizing parts and assemblies in development, determined by their status, identify elements that will be supplied by third-party manufacturers, and determine where the cost and weight of a product are growing by getting lists of parts from the specified weight or cost ranges.

Siemens PLM Software combined its experience in data management in Teamcenter, creating "lightweight" viewers in JT format and large-scale visualization for developing the HD3D technology. Moreover, custom queries based on various criteria can be made and saved for reuse. Combining technologies into a single, easy-to-use environment allows the individual user to clearly understand their tasks and project processes.

- A high-quality modeling software

- Versatility

- Multifunctional

- None